DAMPING

Damping

Adjustments Tube Changes Venting Horn Coupling Damping

Attenuators used in conjunction with earmold modification

influence the center frequencies. The amount of effect is

determined by the density of the attenuator or damping plug,

the number of attenuators used, and the location in the system.

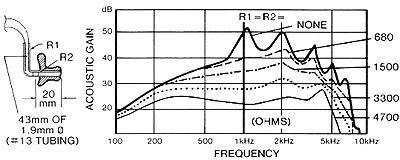

Density is the same as damper resistance or acoustic ohms and it is determined by the material. Sintered balls, fiber plugs, even lambs wool, all create some acoustic resistance and influence the mid-frequencies, some more than others. The greater the density(resistance), the greater the reduction in the peaks of the frequency response. This smoothing effect created by any form of attenuator or damping plug therefore reduces the output and gain of the hearing aid.

There is an additive effect when using dampers. It is important to remember that the damping plug will reduce both gain and output. The placement of the damping plug will influence the frequency response. Generally, the closer the damping plug is to the end of the tubing nearest the earmold, the greater the effect. All manufactured dampers will produce predictable effects on the frequency response of a hearing aid. The effects will vary, however, between hearing aid models, and when coupled to different ear cavities. Lambs wool and other similar material will produce variable acoustic results and should be used accordingly. The dampers available from Mid-States are the 680 ohm, 1500 ohm, and 2300 ohm dampers. Others may be secured and added to the earmold system after it is fabricated.

- Dampers exist in several densities.

- The higher the ohm rating for dampers, the greater the attenuation.

- Moisture build-up in dampers is a common problem. Reduction of the moisture is possible by using an air blower, or the dampers can be replaced.

CONTACT US

Mid-States Laboratories, Inc.

600 N. St. Francis

P.O. Box 1140

Wichita, KS 67201

info@mid-stateslabs.com

Join Our List

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Please try again later